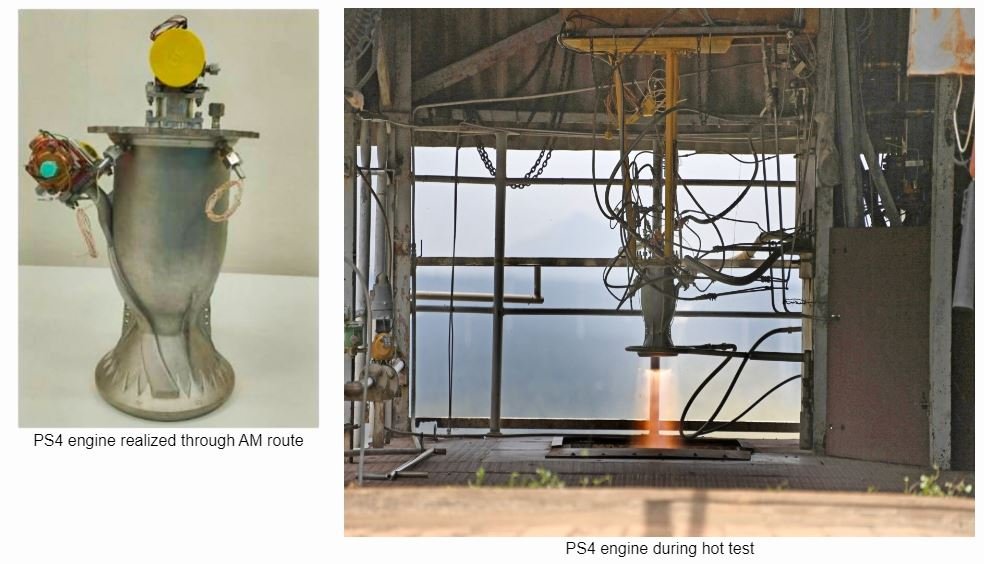

Indian Space Research Organization (ISRO) achieved a milestone by successfully hot testing a liquid rocket engine manufactured through Additive Manufacturing (AM) technology on May 9, 2024.

- The engine tested was the PS4 engine of the PSLV upper stage, traditionally manufactured through machining and welding methods.

- The redesigned engine, using the Design for Additive Manufacturing (DfAM) concept, was produced in a single-piece using Laser Powder Bed Fusion, eliminating 19 weld joints and reducing raw material usage and production time significantly.

- Manufacturing of the engine was carried out by M/s WIPRO 3D, an Indian industry, and hot testing was conducted at ISRO Propulsion Complex, Mahendragiri.

- Prior to hot testing, detailed flow, thermal modeling, structural simulation, and cold flow characterization were carried out, leading to four successful developmental hot tests of integrated engine, validating performance parameters.

- The engine successfully passed the full qualification duration of 665 s during hot testing, meeting expected performance parameters.

- Plans are underway to incorporate this Additive Manufactured PS4 engine into the regular PSLV program.

Q: Which liquid rocket engine did ISRO successfully hot test through Additive Manufacturing (AM) technology on May 9, 2024?

a) PS1 engine

b) PS2 engine

c) PS3 engine

d) PS4 engine

Ans : d) PS4 engine